全站搜索

Search the entire website

Search the entire website

Maximize Mineral Recovery with Our High-Efficiency Spiral Classifiers – Precision Separation for Optimal Results

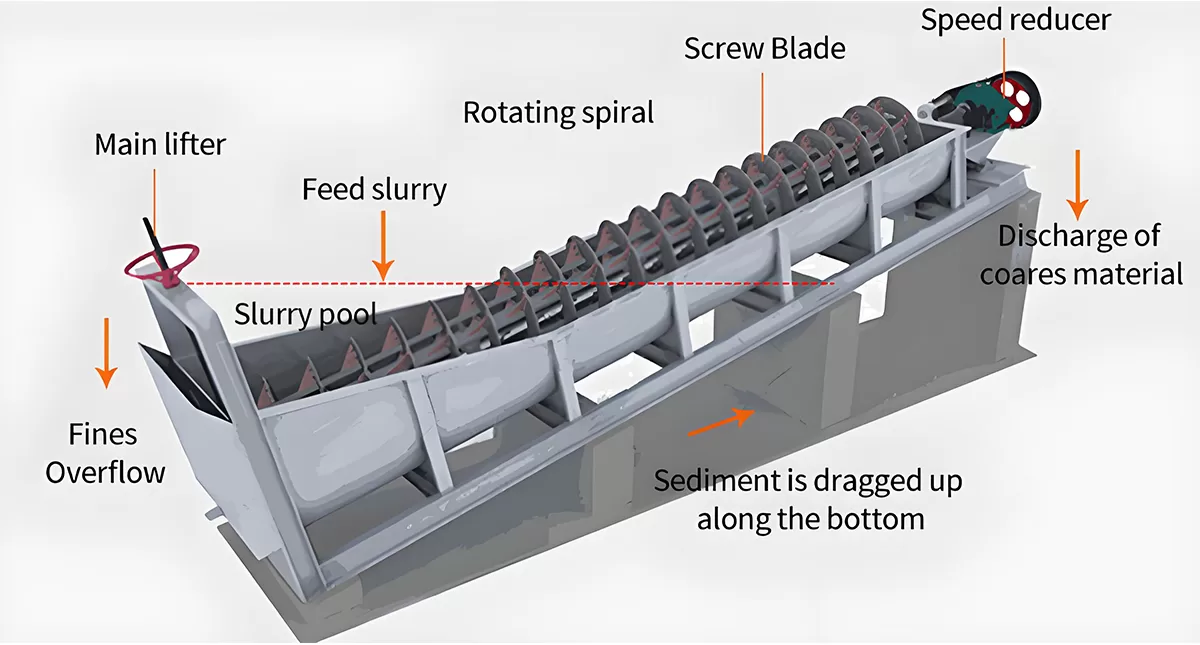

The spiral classifier is one of the equipment for mineral processing. It is a kind of equipment for mechanical classification based on the principle that the specific gravity of solid particles is different and therefore the precipitation speed in the liquid is different. It can filter the powder ground in the ball mill, and then use the spiral blades to rotate the coarse material into the mill feed port, and discharge the filtered fine material from the overflow pipe.

The spiral classifier mainly consists of the following components:

The spiral classifier relies on the principle that the solid particles are different in size and specific gravity, so their sedimentation speed is different in the liquid.

The slurry is stirred by spiral rotation at low speed so that fine particles are suspended in the slurry surface and overflow to the overflow weir.

Coarse particles sink to the bottom of the tank and are conveyed by the screw to the discharge port to be discharged. Generally, the coarse sand is returned to the ball mill for secondary grinding, that is, the spiral classifier and the ball mill form a closed circuit.

| Model | Spiral Diameter (mm) | Trough Length (mm) | Spiral rotate speed (r/min) | Processing capacity(t/d) | Motor Power (kw) | Dimensions (mm≤) | Total weight (t) | ||||

| Sand -return | Overflow | For driving | For lifting | Length | Width | Height | |||||

| FG-3 | 300 | 3000 | 12-30 | 80-150 | 20 | 1.1 | —- | 3850 | 490 | 1140 | 0.7 |

| FG-5 | 500 | 4500 | 8-12.5 | 135-210 | 32 | 1.1 | —- | 5430 | 680 | 1480 | 1.9 |

| FG-7 | 750 | 5500 | 6-10 | 340-570 | 65 | 3 | —- | 6720 | 980 | 1820 | 3.1 |

| FG-10 | 1000 | 6500 | 5-8 | 675-1080 | 110 | 5.5 | —- | 7590 | 1240 | 2380 | 4.9 |

| FC-10 | 8400 | 675-1080 | 85 | 7.5 | —- | 9600 | 1240 | 2680 | 6.2 | ||

| FG-12 | 1200 | 6500 | 4-6 | 1170-1870 | 155 | 7.5 | 2.2 | 8180 | 1570 | 3110 | 8.5 |

| FC-12 | 8400 | 1170-1870 | 120 | 7.5 | 2.2 | 10370 | 1540 | 3920 | 11.0 | ||

| 2FG-12 | 6500 | 2340-3740 | 310 | 15 | 4.4 | 8230 | 2790 | 3110 | 15.8 | ||

| 2FC-12 | 8400 | 2340-3740 | 240 | 15 | 4.4 | 10370 | 2790 | 3920 | 17.6 | ||

| FG-15 | 1500 | 8300 | 4-6 | 1830-2740 | 235 | 7.5 | 2.2 | 10410 | 1880 | 4080 | 12.5 |

| FC-15 | 10500 | 1830-2740 | 185 | 7.5 | 2.2 | 12670 | 1820 | 4890 | 16.8 | ||

| 2FG-15 | 8300 | 2280-5480 | 470 | 15 | 4.4 | 10410 | 3390 | 4080 | 22.1 | ||

| 2FC-15 | 10500 | 2280-5480 | 370 | 15 | 4.4 | 12670 | 3370 | 4890 | 30.7 | ||

| FG-20 | 2000 | 8400 | 3.6-5.5 | 3290-5940 | 400 | 11-15 | 3 | 10790 | 2530 | 4490 | 20.5 |

| FC-20 | 12900 | 3210-5940 | 320 | 11-15 | 3 | 15610 | 2530 | 5340 | 28.5 | ||

| 2FG-20 | 8400 | 7780-11880 | 800 | 22-30 | 6 | 11000 | 4600 | 4490 | 35.5 | ||

| 2FC-20 | 12900 | 7780-11880 | 640 | 22-30 | 6 | 15760 | 4600 | 5640 | 48.7 | ||

| FG-24 | 2400 | 9130 | 3.67 | 6800 | 580 | 15 | 3 | 11650 | 2910 | 4970 | 26.8 |

| FC-24 | 14130 | 6800 | 490 | 18.5 | 4 | 16580 | 2930 | 7190 | 41.0 | ||

| 2FG-24 | 9130 | 13600 | 1160 | 30 | 6 | 12710 | 5430 | 5690 | 45.8 | ||

| 2FC-24 | 14130 | 13700 | 910 | 37 | 8 | 17710 | 5430 | 8000 | 67.9 | ||

| 2FG-30 | 3000 | 12500 | 3.2 | 23300 | 1785 | 40 | 8 | 16020 | 6640 | 6350 | 73.0 |

| 2FC-30 | 14300 | 23300 | 1410 | —- | —- | 17091 | —- | 8680 | 84.8 | ||

A Spiral Classifier is a mechanical device used to separate solids from liquids or to separate solids based on particle size, typically after milling or crushing.

The classifier uses a rotating spiral to convey larger, settled particles up an inclined trough while finer particles are carried away in the overflow liquid.

Spiral Classifiers provide efficient particle size classification, dewatering, and washing of materials, resulting in a more uniform product size distribution.

They are commonly used in mineral processing, chemical processing, wastewater treatment, and aggregate production to control particle size and remove unwanted fines.

Spiral Classifiers are suitable for processing minerals, sand, aggregates, and other granular materials requiring size separation or dewatering.