全站搜索

Search the entire website

Search the entire website

Cone crusher is designed and developed based on many advantages of conventional cone crusher, jaw crusher and impact crusher, which is widely used in mining, metallurgy, construction, hydropower, transportation, chemical industry, building materials industry, etc.

Cone crusher has features of a high crushing ratio, compact structure, accurate control system, good finished particle shape, and prolonged working lifetime. It can be widely used in secondary crushing and fine crushing projects to meet different crushing needs for ore and bulk materials in mining, metallurgy, construction, road, railway, water and chemical industries.

Widely used in medium and fine crushing operations in metallurgy, mining, chemical industry, cement, construction, refractory materials and ceramics and other industries.

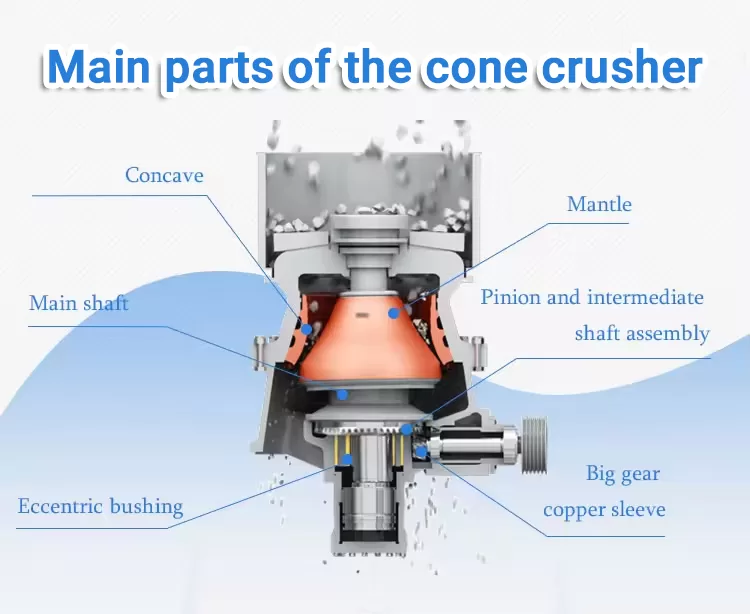

A cone crusher consists of key parts including the rack, horizontal axis, moving cone, balance wheel, eccentric sleeve, upper broken wall (fixed cone), lower broken wall (moving cone), fluid coupling, lubrication system, hydraulic system, etc. Cone crusher wear parts, the most often replaced parts are the frame liners, mantle liners, bowl liners.

The single-cylinder hydraulic cone crusher is an ideal choice for crushing medium to hard materials, thanks to its efficient performance and smart hydraulic system.

During operation, the motor drives the eccentric bushing to rotate, causing the crushing cone to move in an eccentric motion. Materials are repeatedly compressed and bent between the crushing cone and the bowl liner until they are crushed to the desired size and discharged.

The advanced hydraulic system allows precise adjustment of the discharge opening and provides overload protection, ensuring safe and reliable operation.

| Model | Cavity Type | Maximum feed inlet Size (mm) | Minimum Discharge Opening (mm) | Capacity (t/h) | Maximum installed power (kw) |

| SH420 | S1 Extra coarse | 240 | 22 | 85-170 | 90 |

| S2 Medium coarse | 200 | 19 | 70-130 | ||

| SH420 | H1 Fine | 135 | 10 | 45-130 | |

| H2 Medium fine | 65 | 8 | 35-80 | ||

| H3 Extra fine | 38 | 4 | 27-60 | ||

| SH430 | S1 Extra coarse | 360 | 25 | 120-345 | 160 |

| S2 Medium coarse | 300 | 22 | 105-305 | ||

| S3 Extra coarse | 235 | 19 | 90-275 | ||

| SH430 | H1 Fine | 185 | 13 | 60-210 | |

| H2 Medium fine | 90 | 10 | 65-165 | ||

| H3 Extra fine | 50 | 6 | 48-105 | ||

| SH440 | S1 Extra coarse | 450 | 35 | 255-605 | 250 |

| S2 Medium coarse | 400 | 29 | 215-515 | ||

| S3 Extra coarse | 300 | 25 | 190-490 | ||

| SH440 | H1 Fine | 215 | 16 | 110-395 | |

| H2 Medium fine | 110 | 13 | 115-340 | ||

| H3 Extra fine | 70 | 8 | 90-225 | ||

| SH660 | S1 Extra coarse | 560 | 41 | 355-1050 | 315 |

| S2 Medium coarse | 500 | 38 | 305-895 | ||

| SH660 | H1 Fine | 275 | 16 | 170-665 | |

| H2 Medium fine | 135 | 16 | 190-505 | ||

| H3 Extra fine | 65 | 13 | 205-320 |

A cone crusher is a compression-type crusher that reduces material by squeezing it between a rotating mantle and a stationary bowl liner. Used for secondary and tertiary crushing. Highly effective crushing equipment.

Cone crushers offer high capacity, efficient reduction ratios, and produce a more cubical product compared to some other crusher types. Delivers consistent crushing performance.

Cone crushers are versatile and can crush a variety of materials, including rock, ore, and aggregates. Suitable for many crushing applications.

A cone crusher uses an eccentric motion to squeeze material between a rotating mantle and a stationary bowl liner until it fractures. Achieves efficient material reduction.

Regular maintenance includes inspecting and replacing wear parts (liners), checking lubrication levels, and monitoring performance. Ensures long crusher lifespan and reliability.