全站搜索

Search the entire website

Search the entire website

Stone Jaw Crusher machine is kind of coarse crusher, mainly used in mining, building materials, infrastructure construction etc. The stone crusher machine can crush various materials with compressive strength not exceeding 320MPa.

When you need a powerful crushing operation and are looking for an efficient and stable crushing solution, our jaw crusher is the right choice for you. As a highly acclaimed crushing equipment in the industry, the jaw crusher meets your needs in different crushing scenarios with its excellent performance, simple operation and outstanding durability. Whether it is mining, construction crushing or highway and railroad construction, it can easily perform and bring you considerable production benefits.

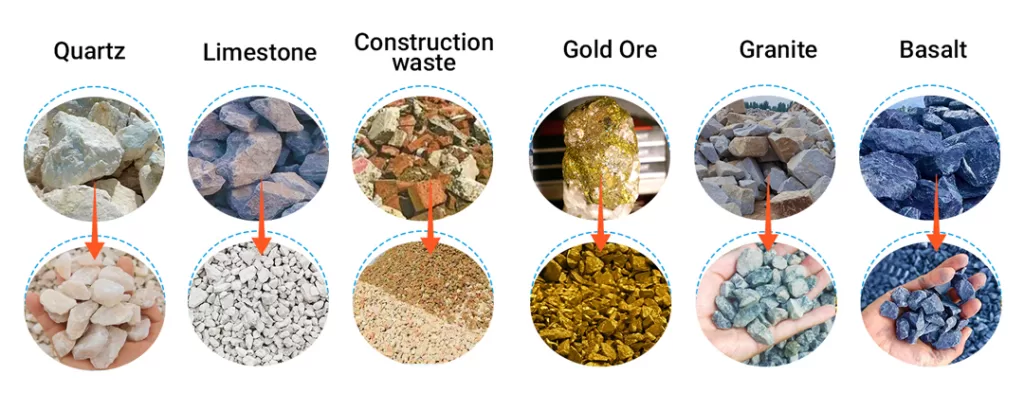

Jaw crusher applied materials: limestone, pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, coal gangue, construction waste, ferrosilicon, basalt, sandstone, rocks, ore, glass, cement clinker and some metal.

① Deep crushing cavity which improves capacity.

② High crushing ratio and uniform finished production size.

③ Single jaw crusher can save power 15% – 30%

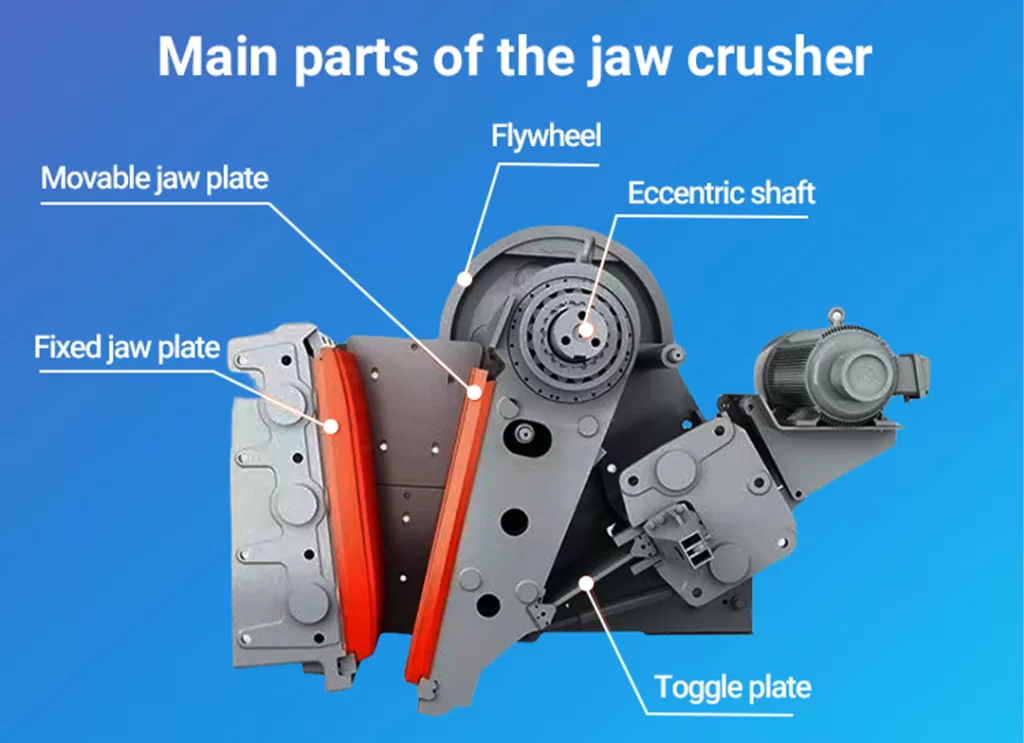

Here’s how a stone jaw crusher operates: First, the motor provides the power. It turns the belt wheel, which in turn makes the eccentric shaft rotate. This shaft’s rotation causes the movable jaw plate to swing rhythmically. It moves towards the fixed jaw plate and then away from it, over and over. This action creates strong forces – pressing, rubbing, and grinding – on the raw stone material placed between the jaws. As the stone gets crushed smaller, it gradually falls downwards. Once the particles reach the desired size setting, they are discharged from the bottom opening of the crusher.

As ideal primary or secondary crusher equipment, stone jaw crusher machines with different types are often used in various industries. Depending on different ways of moving or engine, stone jaw crushers are divided into three types: PE/PEX Motor jaw crusher, Diesel jaw crusher, and Mobile jaw crusher.

| Model | Feeder Opening Size(mm) | Max. Feeding Size (mm) | Discharging Opening Size(mm) | Capacity (t/h) | Motor Power (kw) | Overall Dimension (mm) |

| PE400x600 | 400×600 | 350 | 40-90 | 15-60 | 30 | 1700x1750x1680 |

| PE500x750 | 500×750 | 425 | 50-100 | 40-130 | 45 | 2150x1900x1950 |

| PE600x900 | 600×900 | 500 | 60-125 | 90-180 | 55 | 2500x2010x2350 |

| PE750x1060 | 750×1060 | 630 | 60-150 | 110-380 | 110 | 2630x2310x3110 |

| PE900x1200 | 900×1200 | 750 | 95-165 | 220-450 | 132 | 3720x2850x3250 |

| PE1000x1200 | 1000×1200 | 850 | 200-300 | 280-560 | 160 | 3820x2850x3250 |

| PE1200x1500 | 1200×1500 | 1020 | 150-300 | 400-800 | 220 | 3710x3446x4075 |

| PE1500x1800 | 1500×1800 | 1200 | 210-360 | 520- 1100 | 280 | 5100x4700x4300 |

Selection hinges on material characteristics (max feed size, hardness, abrasiveness), required throughput (tph), desired output size (CSS), available motor power, and budget. Careful analysis ensures optimal, cost-effective performance.

Proper installation requires a robust, level foundation and precise alignment. Correct operation involves thorough pre-checks, empty start-up, controlled uniform feeding, avoiding overload/choking, and following the proper shutdown sequence.

Daily checks include fasteners, lubrication, and visual inspection of wear parts. Regular maintenance involves deeper inspections and component servicing. Extend jaw plate life significantly through proper material selection, uniform feeding, pre-screening, and strategically rotating or flipping the plates.

Common faults include sudden stops (choking), reduced output, jaw plate issues, bearing overheating, excessive vibration, and toggle plate breakage. Troubleshooting involves systematically identifying causes like blockages, wear, loose parts, or improper settings.

Jaw crushers excel at primary crushing of large, hard materials due to their robustness. Cone crushers are better suited for secondary/tertiary hard rock crushing, offering higher reduction and better shape. Impact crushers produce excellent cubical product but wear much faster on hard, abrasive rock.