全站搜索

Search the entire website

Search the entire website

ball mill is a key piece of equipment used for grinding various materials into fine powder. It uses a rotating cylinder filled with grinding media, typically steel balls, to achieve size reduction through impact and abrasion.

The core purpose of a ball mill is size reduction. It grinds coarse feed material down to a much finer particle size required for processes like mineral liberation, flotation, or cement production.

Ball mills are essential in many industries, especially mineral processing. They take crushed ore, often measured in millimeters or centimeters, and grind it down to microns. This fine grinding is necessary to liberate valuable minerals locked within the waste rock (gangue). Once liberated, these minerals can be separated using methods like flotation or leaching. Ball mills are also widely used in cement plants to grind clinker and other additives into the final cement powder. They are robust machines designed for continuous, heavy-duty operation, handling large volumes of material effectively. Think of them as the workhorses that prepare materials for the next crucial steps in your process.

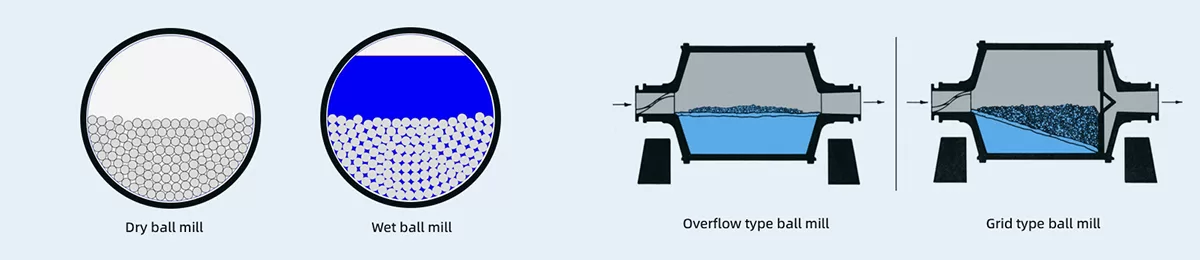

Overflow type ball mill: the slurry is discharged through the overflow port at the end of the cylinder, simple structure, suitable for fine grain grinding.

Lattice type ball mill: the cylinder end is equipped with lattice plate, forced discharge, the product size is coarse, the processing capacity is larger.

Wet ball mill: widely used in metal ore beneficiation, such as gold, chromium, tin, coltan, tantalite, silica sand, lead, pebbles and so on.

Dry ball mill: commonly used in cement, building stone (such as limestone, gypsum, etc.), electric power (such as coal powder preparation) and other industries.

Customized production line design is based on your specific material characteristics (e.g., hardness, initial particle size, target fineness), production requirements, and site conditions. This includes ball mill selection (dry or wet, size and dimensions), configuration of the feed system, discharge system, conveying system, and classifying equipment (if finer size control is required).

If you are interested in ball mill, please feel free to contact us! We will provide you with more than two solutions for you to choose from.

Grinding Media:

Commonly used ball sizes: Φ40mm, Φ60mm, Φ80mm, Φ100mm, Φ120mm (can be customized according to requirements).

Ball Mill Liner:

| Model | Rotate speed (r/min) | Grinding media Weight (T) | Feed size (mm) | Discharge size (mm) | Capacity (t/h) | Motor power (KW) | Weight (T) |

| Φ900×1800 | 36 | 1.5 | ≦20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.5 |

| Φ900×3000 | 38 | 2.7 | ≦20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.7 |

| Φ1200×2400 | 36 | 3 | ≦25 | 0.075-0.6 | 1.5-4.8 | 30 | 12 |

| Φ1200×3000 | 36 | 3.5 | ≦25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| Φ1200×4500 | 36 | 5 | ≦25 | 0.074-0.4 | 11.6-5.8 | 55 | 13.8 |

| Φ1500×3000 | 32.4 | 7.5 | ≦25 | 0.074-0.4 | 2-5 | 75 | 16.8 |

| Φ1500×4500 | 29.7 | 11 | ≦25 | 0.074-0.4 | 3-6 | 110 | 21 |

| Φ1500×5700 | 27 | 12 | ≦25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Φ1830×3000 | 25.4 | 11 | ≦25 | 0.074-0.4 | 4-10 | 130 | 29 |

| Φ1830×4500 | 25.4 | 15 | ≦25 | 0.074-0.4 | 4.5-12 | 155 | 35.5 |

| Φ1830×6400 | 24.1 | 21 | ≦25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Φ1830×7000 | 24.1 | 23 | ≦25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Φ2100×3000 | 23.7 | 15 | ≦25 | 0.074-0.4 | 6.5-36 | 155 | 34.8 |

| Φ2100×4500 | 23.7 | 24 | ≦25 | 0.074-0.4 | 8-43 | 245 | 42 |

| Φ2100×7000 | 23.7 | 26 | ≦25 | 0.074-0.4 | 8-48 | 280 | 56.6 |

| Φ2200×4500 | 21.5 | 27 | ≦25 | 0.074-0.4 | 9-45 | 280 | 51.8 |

| Φ2200×6500 | 21.7 | 35 | ≦25 | 0.074-0.4 | 14-26 | 380 | 60 |

| Φ2200×7000 | 21.7 | 35 | ≦25 | 0.074-0.4 | 15-28 | 380 | 62 |

| Φ2200×7500 | 21.7 | 35 | ≦25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Φ2400×3000 | 21 | 23 | ≦25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Φ2400×4500 | 21 | 30 | ≦25 | 0.074-0.4 | 8.5-60 | 320 | 69 |

| Φ2700×4000 | 20.7 | 40 | ≦25 | 0.074-0.4 | 12-80 | 380 | 94 |

| Φ2700×4500 | 20.7 | 48 | ≦25 | 0.074-0.4 | 12-90 | 480 | 102 |

| Φ3200×4500 | 18 | 65 | ≦25 | 0.074-0.4 | 25-120 | 630 | 137 |

| Φ3600×4500 | 17 | 90 | ≦25 | 0.074-0.4 | 25-140 | 850 | 158 |

| Φ3600×6000 | 17 | 110 | ≦25 | 0.074-0.4 | 25-160 | 1250 | 175 |

| Φ3600×8500 | 18 | 131 | ≦25 | 0.074-0.4 | 45.8-256 | 1800 | 252 |

| Φ4000×5000 | 16.9 | 121 | ≦25 | 0.074-0.4 | 45-208 | 1500 | 203 |

| Φ4000×6000 | 16.9 | 146 | ≦25 | 0.074-0.4 | 65-248 | 1600 | 218 |

| Φ4000×6700 | 16.9 | 149 | ≦25 | 0.074-0.4 | 45-252 | 1800 | 238 |

| Φ4500×6400 | 15.6 | 172 | ≦25 | 0.074-0.4 | 54-306 | 2000 | 280 |

ZONEDING Machine specializes in providing custom-designed mobile ball mills, offering unparalleled flexibility and efficiency for your on-site grinding needs. Unlike traditional, fixed-position ball mills, our mobile units are engineered for convenient transportation and usage across various locations. This means you can bring the processing power directly to your material, eliminating the costly and time-consuming process of transporting materials to a separate facility.

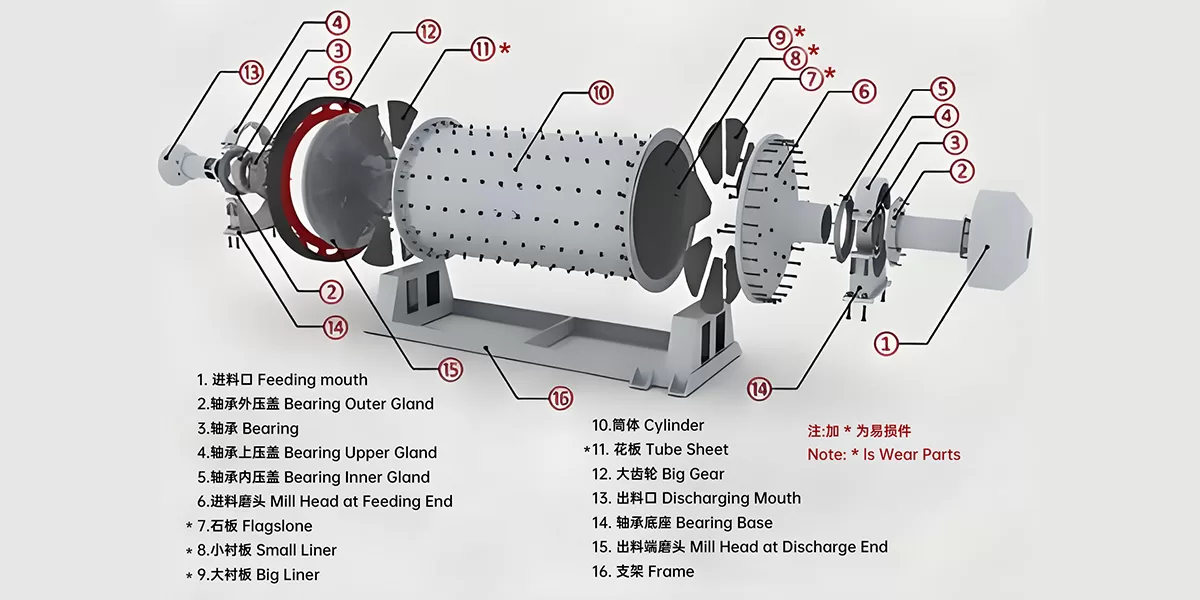

The ball mill consists of feeding part, discharging part, rotary part, transmission part (reducer, small transmission gear, motor, electric control) and other main parts. The hollow shaft is made of cast steel with removable lining, the large gear of rotary is hobbing processed by casting, and the cylinder body is embedded with wear-resistant lining plate, which has good abrasion resistance.

The material enters the cylinder through the feeding part and the feeding part. The grinding media (steel ball/ceramic ball) in the cylinder will generate centrifugal force with the material with the cylinder rotating, when the media is lifted to a certain height and then thrown down according to gravity, the material will be crushed under the impact of grinding media on the material, and the crushed material will be discharged out of the machine through the outlet with the help of the thrust of the feeding material and the flushing water to complete the whole grinding process.

ZONEDING Machine is dedicated to providing efficient and reliable solutions. With over 20 years of ball mill technology experience, we produce durable and robust ball mills that deliver higher value at lower costs.

Media choice depends on material hardness, abrasiveness, and final fineness needs (steel balls = high hardness/efficiency; ceramic = prevents contamination). Filling amount (charge ratio) is typically 30%-45% of the effective mill volume, adjusted based on operating conditions for optimal efficiency.

Critical speed is the theoretical minimum speed where balls start centrifuging with the shell instead of cascading. Actual operating speed is usually 65%-80% of critical speed; too high or too low reduces grinding efficiency (too high = no impact, too low = weak impact).

Different liner shapes affect the trajectory and lifting height of the grinding media. Wave/step liners lift balls higher, increasing impact and grinding action, boosting efficiency, but may wear faster. Smooth liners rely more on attrition.

Wet grinding: Higher efficiency, no dust, easy material transport, allows simultaneous classification. Con: Needs dewatering. Dry grinding: Product doesn’t need drying, simpler structure. Cons: Dusty, slightly lower efficiency, potential overgrinding. Mineral processing almost always uses wet; cement and certain chemicals require dry.

Main wear parts are liners and large/small gears (or other transmission components). Maintenance focus: Regularly check liner wear and tightness, bearing temperature and lubrication, gear meshing, and anchor bolt tightness.

Mill discharge goes into the classifier. The classifier sends correctly sized fines out and returns oversized coarse material back to the mill for re-grinding. This forms a closed circuit, improving efficiency, preventing over-grinding, and ensuring uniform product size.