全站搜索

Search the entire website

Search the entire website

Tire type mobile cone crusher station is mainly used in metallurgy, chemical industry, building materials, water and electricity industries for processing materials need to be moved, especially used for stone crushing in highways, railways, hydroelectric projects and other liquidity operations.

A mobile cone crusher is ideal because its compression crushing handles hard, abrasive rock effectively. It creates the cubical product shape needed for high-specification aggregates. Plus, its mobility allows flexible operation on different sites or within large quarries, reducing transport costs.

Mobile cone crushers mainly work in secondary or tertiary crushing stages. They are common in mining, quarrying (aggregate production), and construction waste recycling industries, especially for hard and abrasive materials.

Mobile cone crushers are versatile workhorses found in several demanding sectors:

Niche Applications: They also process materials like slag (steel, copper), quartz, and other hard industrial minerals where mobility and product shape are important.

Mining: Essential for breaking down hard ores like iron, copper, gold, and basalt after primary crushing. Their ability to handle abrasive materials makes them durable choices.

Aggregate Production: Widely used in quarries to produce high-quality cubical aggregate from materials like granite, river stone, and limestone for concrete, asphalt, and construction fill.

Construction Waste Recycling: Effective at processing crushed concrete and asphalt into reusable aggregates. Their mobility is a huge plus for temporary recycling sites.

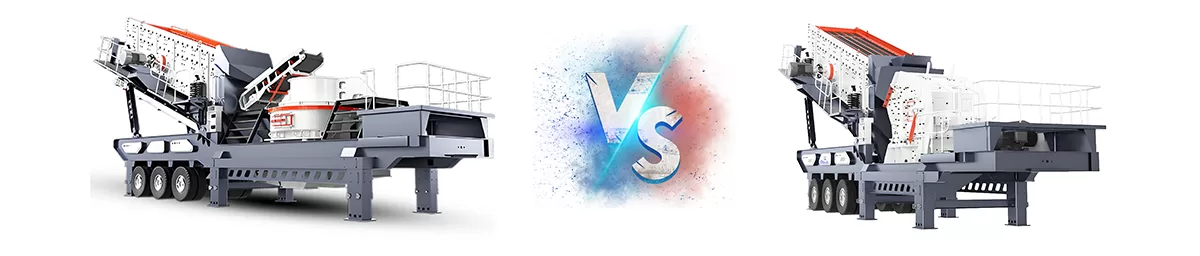

Making the wrong decision leads to inefficiency or even equipment damage. Understanding their strengths guides the right choice.

A mobile cone crusher has the advantage with very hard and abrasive materials like granite or basalt. A mobile impact crusher generally works better with softer, less abrasive materials like limestone and performs well in recycling applications.

Here’s a quick comparison:

| Feature | Mobile Cone Crusher | Mobile Impact Crusher |

|---|---|---|

| Hardness | Best for Hard / Very Hard | Best for Soft / Medium-Hard |

| Abrasiveness | Handles High Abrasiveness Well | Sensitive to High Abrasiveness |

| Reduction Ratio | Lower (typically 3:1 to 5:1) | Higher (can be 10:1 to 20:1) |

| Fines Output | Generally Lower | Generally Higher |

| Product Shape | Excellent Cubical Shape | Good Cubical Shape (esp. in recycling) |

| Common Use | Secondary/Tertiary, Hard Rock Quarry | Primary/Secondary, Limestone, Recycling |

Essentially, if you’re dealing with tough, abrasive feed and need a cubical product in secondary or tertiary stages, the mobile cone crusher is likely your machine. If you have softer rock, need a higher reduction ratio in one pass, or are focused on recycling, a mobile impact crusher be better.

Mobile cone crushers offer different cavity (liner) types. Choosing incorrectly leads to poor performance, high wear, and frustration. Matching the cavity to your feed material and desired product is crucial.

Select the crushing cavity (like Fine, Medium, Coarse, Extra Coarse) based on the feed size distribution and the target product size. The right cavity ensures efficient crushing and optimal liner wear.

| Model | ZDM3S185GYS300 | ZDM3S216GYS400 | ZDM3S216HP300 |

| Transportation Length(mm) | 14500 | 15000 | 16000 |

| Transportation Width(mm) | 3000 | 3000 | 4550 |

| Transportation Height(mm) | 4400 | 4500 | 17000 |

| Maximum Length(mm) | 17000 | 16000 | 4600 |

| Maximum Width(mm) | 3400 | 3900 | 6900 |

| Maximum Height(mm) | 5800 | 6500 | 4700 |

| Weight(t) | 34.5 | 49.5 | 41 |

| Tyre Configuration | biax fitted | triaxial fitted | triaxial fitted |

| Tire Configuration | GYS300 | GYS400 | HP300 |

| Feeding Belt Conveyor | B650×15M×2 | B800×15M×2 | B800×15M×2 |

| Discharging Belt Conveyor | B650×14M | B800×14M | B800×16M |

| Conveyor Belt for final products | B500×15M | B800×6M | B650×15M×2 |

| Under vibrating screen | B800×7M | B800×8M | B800×9M |

| Vibrating Screen Model | 3YK1854 | 3YK2160 | 3YK2160 |

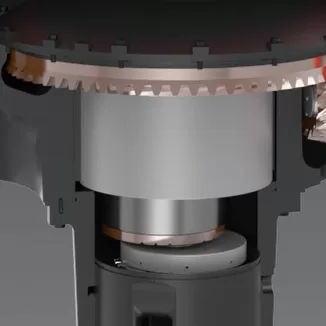

Choosing the right liner set (mantle and bowl liner) goes beyond just picking a name. It’s about optimizing the crushing process.

Zoneding offer various profiles, generally categorized by the feed opening size they accept:

Mobile cone crushers work hard, and parts wear out. Unplanned downtime for replacements and high consumable costs can eat into profits. Knowing the wear life and cost is essential for budgeting and maintenance planning.

The main wear parts are the mantle (on the cone head) and the bowl liner/concave (lining the upper frame). Their lifespan varies greatly depending on material abrasiveness, feed conditions, and operation. Replacement costs are significant but predictable.

Managing wear parts effectively is key to controlling operating costs.

You can maintain consumable parts and improve crusher performance by paying attention to the following factors:

Regular checks prevent minor issues from becoming major problems, especially given the harsh conditions mobile units face.

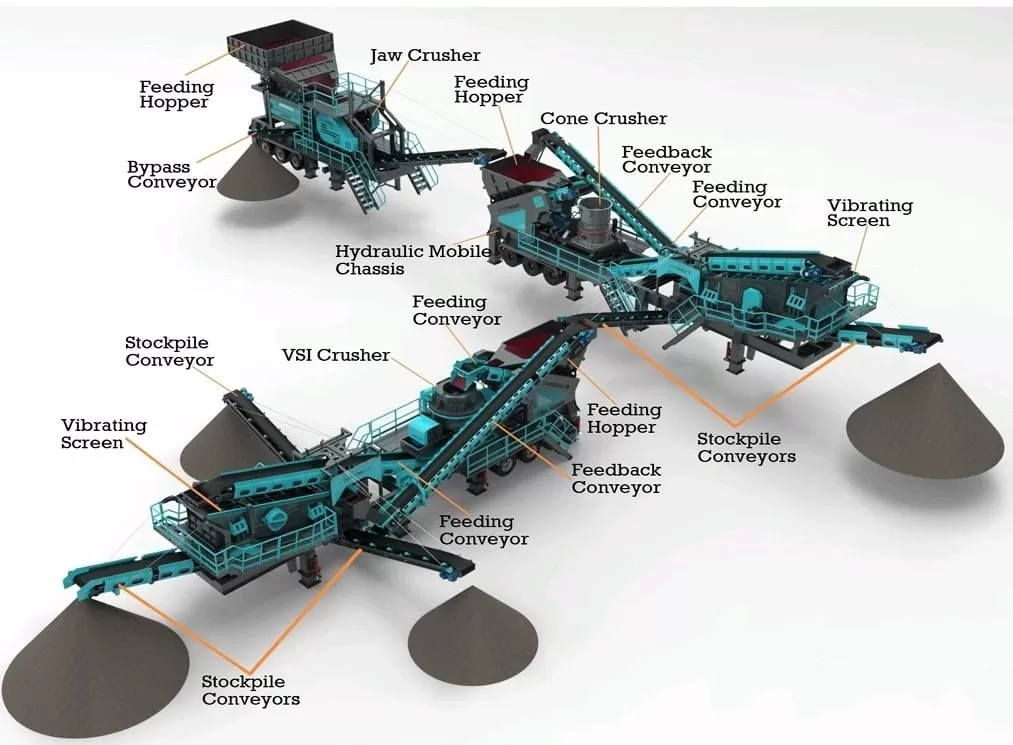

A mobile cone crusher rarely works alone. It needs feeding and its product needs sizing. Mis-matched equipment in the line creates bottlenecks and inefficiency. Understanding common setups helps plan a productive system.

A mobile cone crusher usually works after a mobile primary jaw crusher and before a mobile screening plant. The jaw crusher handles large feed, the cone reduces it further, and the screen separates products.

Creating an efficient mobile production line involves combining the right units.

The most common setup for hard rock processing involves three main mobile units:

Choosing a supplier for a major investment like a mobile cone crusher is critical. A poor choice can lead to unsuitable equipment, inadequate support, and costly problems. Evaluating suppliers carefully minimizes risk.

Look for a supplier with proven manufacturing capability, high-quality components, reliable parts availability, strong technical support (including application knowledge), and verifiable experience in mobile crushing solutions.

Partnering with the right supplier ensures you get equipment that performs and support you can count on.

Our extensive global reach, with exports to over 130 countries across Europe, Africa, Asia, the Americas, and Australia, is underpinned by mature and well-established logistics conditions. This ensures efficient, reliable, and timely delivery of both complete mobile crushing plants and essential spare parts directly to your site, minimizing potential delays and supporting your operation effectively, wherever it is located in the world.

A Mobile Cone Crusher is a portable crushing machine, often wheel- or track-mounted, employing a cone-shaped crushing chamber for material reduction.

It crushes material between a rotating mantle and a stationary bowl liner, providing consistent particle size reduction for secondary or tertiary crushing.

Mobile Cone Crushers offer portability, efficient crushing for consistent product, and on-site material processing for reduced transportation costs.

They’re ideal for quarrying, mining, aggregate production, and construction sites requiring flexible crushing and material sizing solutions.

Mobile Cone Crushers are excellent for hard and abrasive materials like granite, basalt, gravel, and recycled concrete, providing precise sizing.