全站搜索

Search the entire website

Search the entire website

20+ Years of Experience, Delivering Customized Drying Solutions to 1000+ Clients Worldwide.

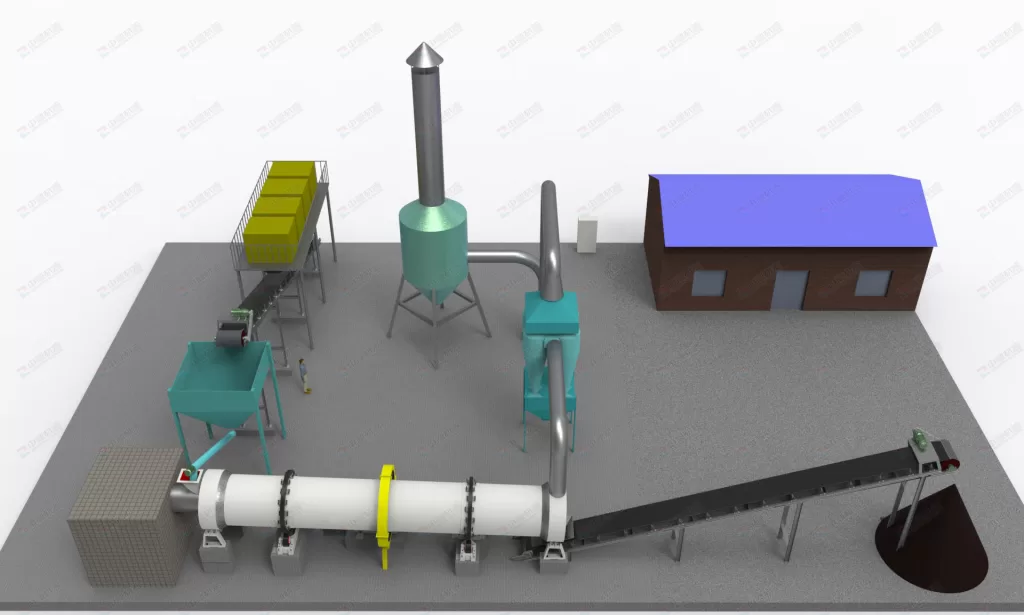

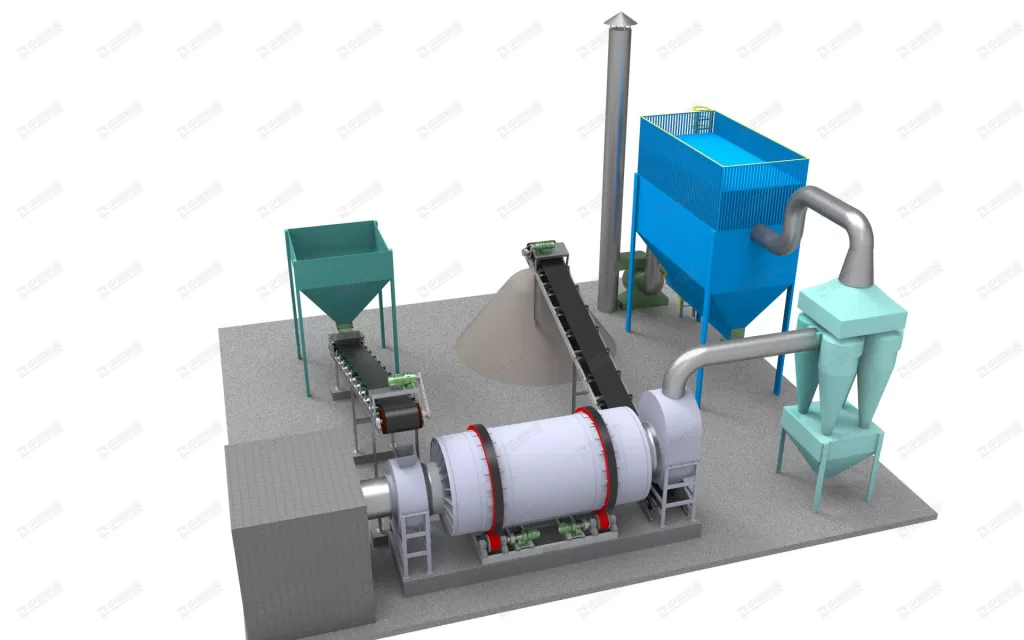

Zoneding Machine offers a versatile range of rotary drying machines, engineered to provide efficient and uniform drying for a wide array of bulk solids. These rotary dryers stand out for their robust construction and ability to deliver consistent results, regardless of feedstock variability. Operating on a simple yet effective principle, the mining machinery tumbles material within a rotating drum, utilizing direct or indirect.

Our dryer equipment helps industries like mineral processing, cement, fertilizer, agriculture, and construction to reduce moisture in bulk solids, from grains and minerals to powders and granules. We offer customized industrial drying solutions:

Our systems are used for sand/rock/aggregate, as well as silted fly ash, sewage sludge, organic fertilizer, coal, bulk materials and biomass. We design and build our systems, integrate related plant systems and have full EPC capabilities.

Single drum dryer is of strong adaptability to kind of materials. This rotary drum dryer is the most commonly used drying equipment in cement plant for drying limestone, clay, coal powder and mixed materials and widely used in metallurgy, mining, electricity, chemical industry, and other sectors.

Three-drum dryer is also known as a three-cylinder dryer or a three-drum dryer. It is an improved version based on a single drum dryer and is supported by modern and advanced German technology. The three-cylinder dryer is mainly composed of three concentric circles of different diameters.

The sand dryer is ideal for drying sand below 30 mm in construction and industrial processes.

Applied Materials: River sand, quartz sand, artificial sand, silica sand, yellow sand, mineral sand, ore, slag, blast furnace slag, fly ash, cinder, etc. in building materials, ore dressing process, coal industry and power plant , etc.

Coal dryer is a new type drying equipment grown from rotary dryer to dry all kinds of coal. Coal itself is usually of high humidity and high agglutination.

Sawdust dryer has high drying intensity, short drying time, large production capacity, high efficiency, small occupied area, easy operation and maintenance, etc. It is also known as sawdust drying machine or sawdust rotary dryer. Mainly, there are two types of sawdust dryer machine named as airflow sawdust dryer and three-channel dryer. The latter is generally used in the sawdust drying process.

Aimed at the adsorptivity and other characteristics of bentonite, bentonite dryer is designed with large capacity. Zoneding bentonite drying technology adopts new grouped lifting blades equipment to improve the material filling rate and extend the stay time of wet bentonite in the cylinder. With improved production efficiency, Zoneding bentonite dryer machine is customized.

Zoneding Machinery is a specialist in the production of various ore powder dryers, including manganese ore powder dryer, nickel ore powder dryer, as well as for drying powder or particle of cobalt, tin, chromium, gold and mercury, etc. This drying equipment is indispensable in the rare metal ore dressing operation.

Desulfurization gypsum has high purity, large free water, fine particle size, and contains impurities such as unreacted calcium carbonate. The gypsum dryer adopts three-layer drum drying technology, which saves one-third of energy compared to traditional dryer and reduces production costs.

To recycle slag produced in ore dressing or smelting industry, Zoneding Machinery develops new advanced dryer for slag drying. Zoneding slag dryer machine is commonly used in building materials, chemical industry, cement, etc.

Sludge drying is a process to dewater and recycle high-moisture sludge as resource. there are mainly two ways to dry sludge, natural drying and mechanical drying. The latter is more efficient. The removal of water reduces the sludge quality and volume, which is to make it convenient to be store and transport the sludge. With mature and advanced international technology from Europe, etc.

The slurry dryer is a rotary dryer that specializes in drying various slurries, including slime, which can be called a slime dryer. In addition, it is used for the drying of sludge, metallic and non-metallic ores, clays in the cement industry, etc. The slurry dryer uses a unique scattering device that disperses the bonded slurry and enters the drying process.

Fruit residue has high moisture content and is difficult to store and transport. Our pomace dryer production line adopts a series of innovative technologies and processes to dry the materials with high sugar content, high water content, and easy adhesion. The pomace with moisture content of about 80% can be quickly pre-dehydrated and dried to a dry product with a moisture content of about 10%.

The sugarcane bagasse dryer adopts high-temperature and rapid drying process. With a large heat transfer coefficient and high thermal efficiency, it can quickly dry sugarcane bagasse to a moisture content of about 12%. The bagasse dryer is specially designed for drying materials with a certain degree of viscosity, and a special scraping device is used inside the drying cylinder to avoid the material sticking to the wall.

Palm fiber dryer is dedicated for drying the waste material from the production of palm oil. After drying, the moisture content of the finished product is less than 15%, which is proper for pelletizing.

The cassava residue dryer is equipped with devices for temperature regulation, material lifting, guiding and dispersing, which effectively avoids wall sticking and blockage. The dried cassava residue material has good color and quality, and is energy-saving and environmentally friendly.

Cocopeat (coconut coir) is the powdery substance between coconut husk fibers. After drying, the coconut peat can be used in the field of plant cultivation or making into coconut bricks, which has high economic benefits.

Distiller is rich in nutrients such as protein, fiber, and trace elements, so it is often used as a high-quality animal feed ingredient.

The spent grain dryer can quickly pre-dehydrate wet brewer’s grains with a moisture content of around 85% to 60%, and then dry them to around 12%. The spent grain dryer can be connected to grinding machine and packaging machine for further processing.

Rotary coolers are designed to cool down products coming from dryers or calciners up to an acceptable temperature for successive handling.

The drying capacity of our rotary dryer systems is from 5 tons per hour to 300 tons per hour. ZONEDING has installed over 80 complete plants around the world following stringent electrical, air pollution control, and safety codes.

ZONEDING Machinery is dedicated to being there for you for the life of your solution.

Discover the various typical examples of ZONEDING Machinery applications for your business.

ZONEDING offers you service support throughout the entire life cycle to ensure the smooth progress of your project:

Q: What is the main function of a mineral processing plant?

A: The main function of a mineral processing plant is to extract valuable minerals or metals from raw ore. It utilizes a series of processes, such as crushing, grinding, screening, gravity separation, magnetic separation, etc., to separate the valuable minerals from the gangue (waste minerals), thereby obtaining a high-grade concentrate product. These plants are designed to maximize efficiency and metal recovery.

Q: What are the key steps involved in mineral processing?

A: Mineral processing typically involves four main stages: first is comminution (crushing and grinding), to reduce the large ore pieces to a suitable particle size; then classification, separating particles based on size; next is concentration, using physical or chemical methods to enrich the target minerals; and finally dewatering, to separate the solid concentrate from water.

Q: What role does mineral processing play in the mining industry?

A: Mineral processing is a crucial link in mining operations. It transforms the mined, low-grade raw ore into a high-grade concentrate, providing suitable raw material for subsequent smelting or metal extraction. Efficient mineral processing is essential for the economic viability and resource utilization of the project, and needs to be completed on schedule and within budget.

Q: What does "particle size control" refer to in mineral processing?

A: In mineral processing, "particle size control" (or "sizing") refers to the process of separating mineral particles based on their size. A common method is screening, which involves passing the material through screens with specific aperture sizes, thereby achieving separation of different size fractions.

Q: How is the efficiency of a mineral processing plant evaluated?

A: A mineral processing plant is usually evaluated by calculating the "recovery rate". The recovery rate is the percentage obtained by dividing the mass of the useful mineral recovered in the final product by the mass of that mineral in the raw material entering the plant. This is a key indicator of how effectively the plant recovers useful minerals from the ore.