全站搜索

Search the entire website

Search the entire website

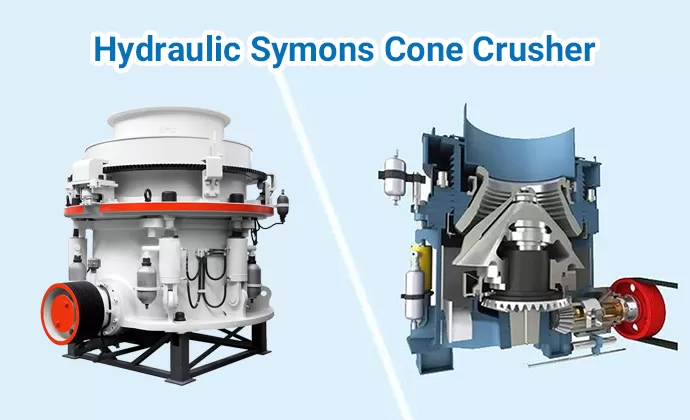

When compared with the traditional cone crusher, The hydraulic cone crusher has higher production capacity, better grain shape of the finished product and high automation degree, which creates more value for customers.

Multi-cylinder Hydraulic Cone Crusher are a new type of cone crushers developed and optimized by our company on the basis of introducing and absorbing European and American hydraulic cone crusher technologies. Compared with other cone crushers, it boasts low energy consumption, large crushing force, high reliability, large production capacity, high degree of automation, simple operation and maintenance, good product shape, low cost of wearing parts, etc.

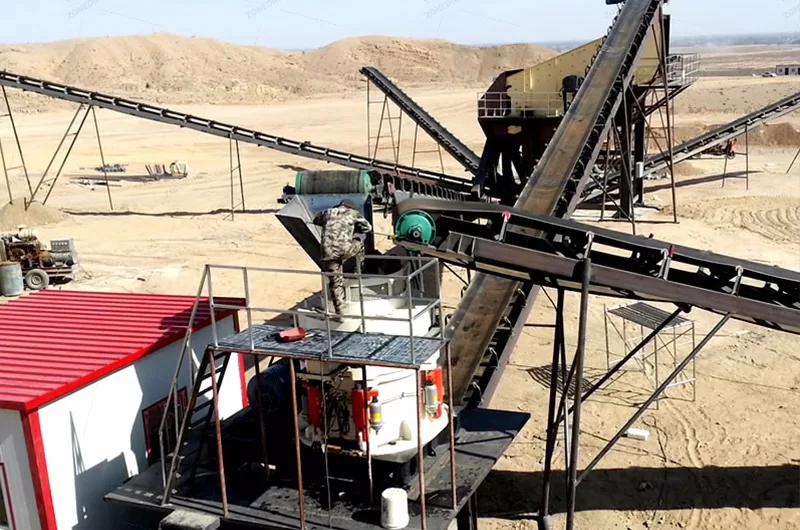

Hydraulic cone crusher can crush materials of above medium hardness, such as iron ores, copper ores, non-ferrous metal ore, limestone, quartz, granite, gritstone, etc. And it is widely used in metallurgy, building, hydropower, transportation, chemical industry, etc. When used in a stone production line, it can be used as secondary, tertiary or quaternary crushing.

Zoneding Machinery provides users with various types of cone crushers such as compound, single-cylinder, multi-cylinder, and full-hydraulic. Complete specifications, affordable price, environmental protection, and energy saving. Our professional technical designers provide free design solutions and provide suitable solutions according to the customer’s site and broken materials.

When Hydraulic cone crusher works, the motor drives the outer copper rotate through V-belt, host pulley, drive shaft, a small bevel gear, a large bevel gear. The outer copper forces crushing cone shaft axis of the outer copper to make rotating swing, making crushing surface sometimes near and sometimes leave the concave surface, so that the material is impacted, squeezed and bent in the ringlike crushing chamber consist of fixed cone and movable cone. After repeated squeezed, shocked, and bent, the material crushing to the required particle size is discharged from the lower part.

The hydraulic adjustment and oil lubrication make the crusher more steady and reliable. It also adopts labyrinth sealing mode, which avoids oil mixing with water easily.

| Model | Cavity | Diameter of large end of crushing cone (mm) | Width of Feeding Opening(mm) | Max.feeding size (mm) | Adjusting Range of Discharge Opening (mm) | Processing capacity(t/h) | Main motor power(kw) | Weight of Main Machine (t) |

| HP200 | C1 | 900 | 210 | 178 | 22~38 | 160~250 | 160 | 10.1 |

| C2 | 155 | 132 | 18~38 | 145~250 | ||||

| C3 | 130 | 110 | 14~38 | 120~250 | ||||

| F1 | 118 | 100 | 12~25 | 108~210 | ||||

| F2 | 90 | 76 | 10~25 | 81~210 | ||||

| F3 | 70 | 60 | 8~25 | 72~210 | ||||

| HP300 | C1 | 1100 | 235 | 200 | 26~45 | 230~445 | 220 | 17.8 |

| C2 | 211 | 180 | 20~45 | 200~445 | ||||

| C3 | 135 | 115 | 16~45 | 180~445 | ||||

| F1 | 124 | 105 | 14~25 | 160~220 | ||||

| F2 | 96 | 82 | 12~25 | 140~220 | ||||

| F3 | 70 | 60 | 8~25 | 120~220 | ||||

| HP400 | C1 | 1400 | 330 | 280 | 26~51 | 270~630 | 315 | 25 |

| C2 | 200 | 170 | 22~51 | 243~630 | ||||

| C3 | 152 | 130 | 16~51 | 210~630 | ||||

| F1 | 135 | 115 | 12~25 | 162~370 | ||||

| F2 | 106 | 90 | 10~25 | 126~370 | ||||

| F3 | 80 | 68 | 8~25 | 104~370 | ||||

| HP500 | C1 | 1500 | 335 | 285 | 32~51 | 365~790 | 400 | 34.1 |

| C2 | 229 | 190 | 25~51 | 328~790 | ||||

| C3 | 180 | 152 | 19~51 | 280~790 | ||||

| F1 | 152 | 130 | 13~25 | 202~450 | ||||

| F2 | 124 | 105 | 10~25 | 158~450 | ||||

| F3 | 88 | 75 | 8~25 | 122~450 |

A hydraulic cone crusher uses hydraulic pressure to adjust settings and provide overload protection. Used for secondary and tertiary crushing of hard to very hard materials. High efficiency crushing solution.

Hydraulic cone crushers offer easy adjustment, high crushing ratio, reliable performance, and overload protection for reduced downtime. Maximize crushing productivity.

Hydraulic cone crushers efficiently crush hard materials like granite, basalt, quartzite, and other abrasive rocks. Ideal for demanding crushing applications.

The hydraulic system allows for quick adjustment of the discharge setting and provides overload protection, minimizing downtime and maximizing throughput. Easy operation and maintenance.

Regularly inspect liners, check hydraulic fluid levels and pressure, and lubricate moving parts. Proactive maintenance ensures optimal performance and extends the crusher’s lifespan.