全站搜索

Search the entire website

Search the entire website

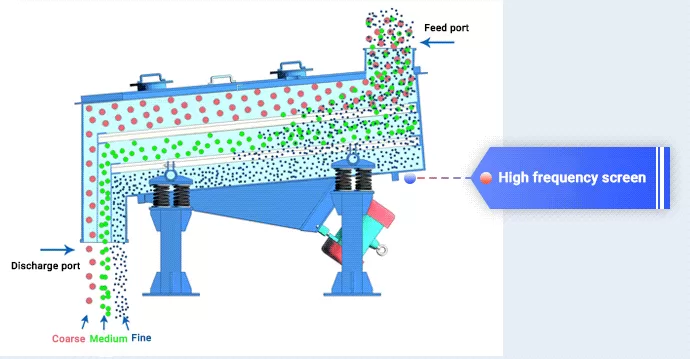

High frequency screen is short for high frequency vibrating screen. As the name suggests, high frequency vibrating screen is the equipment which uses high vibration frequency to screen materials.

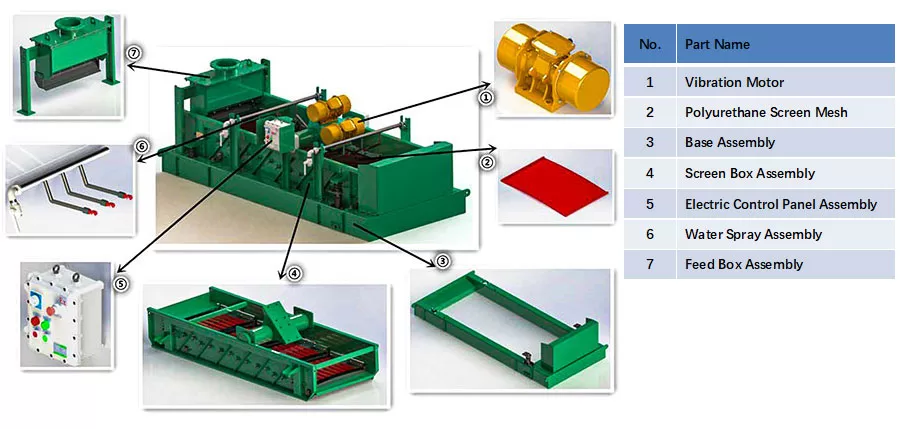

The high frequency vibrating screen is referred to as a high-frequency screen, which is composed of a vibration exciter, a slurry distributor, a screen frame, a frame, a suspension spring, and a screen. It is widely used in mineral processing, coal preparation, chemistry, brick making, food, pharmaceutics, alkali, fertilizer, paper, and other industries.

Iron ore, tin, tungsten, tantalum, niobium sand and other concentrator screening or grading operations, also suitable for mineral processing, coal processing, chemical industry, brick making, food, pharmaceutical, alkali production, chemical fertilizer, paper making and other industries.

High frequency screen consists of vibration exciter, ore pulp distributor, screen frame, machine frame, suspension springs and sieve, etc. This series screen is always used in processing minerals such as ferrous metals including hematite magnet and nonferrous metals including lead, zinc, gold and silver, etc.

High frequency vibrating mesh screen consists of base, frame, support, angle adjustment bar and electronic control box,etc.When the machine operates, the low frequency electromagnetic vibrator vibrates the feeder and outputs part of the mesh screen directly to move the whole screen. At the same time, the high frequency electromagnetic vibrator shakes the middle of mesh screen through the rubber cushion. The mesh screen is composed of three stainless steel screen layers; the lowest screen layer is high strength primary screen; the other two layers are workable screen in mine processing.

| Specification Model | Processing capacity(t/h) | Power (kw) |

| GPS-4 | 15-25 | 0.72 |

| GPS-5 | 20-30 | 1.1 |

| GPS-6 | 24-36 | 1.5 |

| GPS-8 | 32-48 | 2.2 |

A High Frequency Screen is a vibratory screen used for fine particle separation, typically operating at frequencies between 1500-3600 RPM.

High Frequency Screens use rapid vibrations to stratify and separate fine particles through a screen mesh, allowing undersize material to pass through.

High Frequency Screens offer high screening efficiency, increased capacity for fine materials, and reduced blinding compared to conventional screens.

High Frequency Screens are used for processing minerals, coal, sand, and other materials requiring fine particle separation in dry or wet applications.

Consider feed rate, particle size distribution, screen mesh size, vibration frequency, and material moisture content when selecting a High Frequency Screen.