全站搜索

Search the entire website

Search the entire website

Tracked Cone Crusher Station is widely applied in metallurgical, construction, road building, chemical and phosphatic industry.

Fixed plants lack flexibility. Tracked cone crushers bring mobile power directly to your material source.

Tracked cone crushers are vital for secondary, tertiary, or quaternary crushing stages. They excel at processing hard, abrasive rock into precisely sized, cubical aggregate. Their mobility allows flexible deployment across different sites or within large quarries.

Tracked Cone Crushers are workhorses in many industries. They follow primary jaw crushers to refine material further.

Tracked cone crushers primarily work in secondary and tertiary crushing for hard rock like granite or basalt. They produce cubical aggregate for construction. Jaw crushers are for primary crushing, handling larger feed sizes with higher reduction ratios.

Tracked cone crushers are essential in:

Infrastructure Projects: Providing on-site crushing for large construction projects like dams or highways, reducing transport costs.

Aggregate Production: Creating specific sizes (e.g., 0-5mm, 5-10mm, 10-20mm) for concrete, asphalt, and base course from medium-hard to very hard rock.

Mining Operations: Reducing ore size after primary crushing for further processing like grinding or leaching.

Recycling: Processing reclaimed asphalt pavement (RAP) or crushed concrete, although care must be taken with contaminants like rebar.

The fundamental difference lies in their crushing mechanism and stage of use.

| Feature | Tracked Cone Crusher | Tracked Jaw Crusher |

|---|---|---|

| Crushing Stage | Secondary, Tertiary, Quaternary | Primary |

| Feed Size | Smaller (pre-crushed material) | Larger (run-of-quarry rock) |

| Reduction Ratio | Lower (typically 3:1 to 5:1) | Higher (typically 6:1 to 8:1) |

| Crushing Action | Compression between mantle & bowl | Compression between fixed & moving jaw |

| Product Shape | More Cubical | More Slabby/Elongated (can vary) |

| Main Use | Size refinement, shape control | Initial size reduction |

Basically, a jaw crusher does the initial heavy lifting. A cone crusher takes that partially crushed material and refines it to meet stricter size and shape specifications.

Cone crushers use inter-particle compression alongside mantle/bowl compression. This action breaks rock along natural fissures and rounds off edges. The result is a more cubical product, crucial for high-specification aggregate uses.

Producing aggregate that meets quality standards isn’t just about size. Particle shape is extremely important for final product performance, like concrete strength or asphalt stability.

The way a cone crusher works is ideal for creating cubical products:

While cone crushers excel at shape, factors like feed material properties, crusher settings (CSS, speed), and liner profile choice also play significant roles. For applications demanding the absolute best shape, especially in softer or medium-hard rock, sometimes a Vertical Shaft Impactor (VSI) crusher is used in the final stage. However, for hard rock and overall efficiency in secondary/tertiary stages, the cone crusher is often the primary choice for achieving good cubicity.

Choosing the right chamber profile (liner set) is critical for efficiency and meeting specs.

Match the chamber to the job. Use a Coarse chamber for larger feed needing significant reduction. Use Medium for intermediate crushing. Use Fine or Extra-Fine for small feed requiring tight product specs or shaping.

Cone crusher liners (the mantle and bowl liner) define the shape of the crushing chamber. Manufacturers like us at ZONEDING offer different profiles optimized for different tasks. Selecting the correct one is vital.

The main difference lies in the feed opening size and the angle of the crushing zone.

| Factor | Coarse Chamber | Medium Chamber | Fine/Extra Fine Chamber |

|---|---|---|---|

| Primary Goal | Max Reduction (Secondary) | Balanced Reduction/Output | Fine Sizing / Shaping |

| Typical Feed Size | Larger (e.g., 100-250mm) | Medium (e.g., 50-150mm) | Smaller (e.g., < 75mm) |

| Desired Product | Intermediate sizes | Common aggregate sizes | Fine aggregate / Sand |

| Crushing Stage | Secondary | Secondary / Tertiary | Tertiary / Quaternary |

| Key Consideration | Avoid packing with fines | Versatility | Avoid oversize feed |

Important Note: Always consult the manufacturer’s specifications for your specific crusher model. The ideal feed size range (typically 80% passing a certain screen size) for each chamber profile is crucial. Feeding oversized material damages the crusher. Feeding material that is too fine reduces efficiency and can cause packing. Choosing the right chamber maximizes throughput, minimizes wear, and ensures you produce the desired product specification.

Many factors beyond the machine itself impact real-world production rates. Understanding these is key to maximizing output.

Actual throughput depends on feed material characteristics (hardness, moisture, gradation), crusher settings (CSS, chamber), feed method (choke feed), and downstream capacity (screens, conveyors). The crusher’s theoretical capacity is rarely achieved continuously.

Achieving the nameplate capacity (maximum theoretical TPH) of a cone crusher consistently is challenging. Real-world factors significantly influence the actual output.

| Factor Category | Specific Elements | Impact on TPH |

|---|---|---|

| Feed Material | Hardness & Abrasiveness | Harder rock reduces TPH and increases wear. |

| Feed Gradation (Size Distribution) | Too many fines or oversize particles reduce efficiency and TPH. Consistent feed is best. | |

| Moisture Content | High moisture, especially with fines, can cause packing and reduce TPH. | |

| Bulk Density | Denser material means more tons for the same volume. | |

| Clay Content / Stickiness | Can cause packing, blinding screens, reducing overall TPH. | |

| Crusher Settings | Closed Side Setting (CSS) | Tighter CSS = Lower TPH; Wider CSS = Higher TPH. |

| Chamber / Liner Profile | Must match feed size and reduction requirements for optimal TPH. | |

| Crusher Speed (RPM) | Usually optimized by manufacturer, incorrect speed reduces efficiency. | |

| Operational | Feed Method (Choke vs. Trickle) | Consistent choke feeding generally maximizes TPH and improves liner life. |

| Feed Consistency | Surges or interruptions in feed drastically reduce average TPH. | |

| Circuit Design (Closed vs. Open) | Insight: A closed circuit (oversize returned to crusher) can limit TPH if the screen is undersized or if the material creates excessive recirculating load. Sometimes an open circuit feeding a separate screen is more efficient overall. | |

| Downstream | Screen Capacity | Undersized screens downstream bottleneck the crusher, reducing effective TPH. |

| Conveyor Capacity | Belts must handle the crusher output and any recirculating load. | |

| Maintenance | Liner Wear Condition | Worn liners reduce crushing efficiency and TPH. |

| General Machine Condition | Poor maintenance leads to downtime, reducing overall production. |

To maximize actual TPH, you need to control as many of these factors as possible. This means proper feed preparation, selecting the right liners, optimizing CSS, ensuring consistent choke feeding, and making sure the downstream equipment can handle the output.

They look similar but are designed for different crushing stages and feed materials.

Standard head cones have a steeper head angle and larger feed opening. They are typically used for secondary crushing. Short head cones have a flatter head and parallel zone, smaller feed opening, used for tertiary/quaternary fine crushing.

The terms “Standard” and “Short Head” refer to historical cone crusher designs, primarily differing in the shape of the crushing head (mantle) and the corresponding bowl liner. This difference dictates their ideal application.

| Feature | Standard Head Cone | Short Head Cone |

|---|---|---|

| Typical Stage | Secondary | Tertiary / Quaternary |

| Feed Opening | Larger | Smaller |

| Feed Size | Larger (Primary Product) | Smaller (Secondary Product) |

| Head Angle | Steeper | Flatter |

| Parallel Zone | Less Pronounced / Shorter | More Pronounced / Longer |

| Main Goal | High Throughput Reduction | Fine Sizing & Shaping |

| Product Size | Coarser | Finer |

In modern tracked cone crushers, these distinctions are often achieved through different liner profile choices (Coarse, Medium, Fine, Extra Fine) rather than fundamentally different head assemblies. However, the principle remains: select the chamber geometry that best matches the feed size and product requirements for that specific crushing stage.

Typically, a mobile jaw crusher performs primary crushing. Its output feeds the tracked cone crusher for secondary/tertiary reduction. A mobile screen then separates products into required sizes. Oversize can recirculate back to the cone.

Key parameters include crusher size (head diameter), max feed size, CSS range, TPH capacity, engine power, and transport weight/dimensions. Important options are chamber types, pre-screen integration, automation level, and dust suppression.

| Model | WT160SC | WT250SC | WT300HPM | WT400HPM | |

| Dimensions of Transmission Devices | Length | 16800mm | 19000mm | 19000mm | 19500mm |

| Width | 3500mm | 3600mm | 3900mm | 3900mm | |

| Height | 3700mm | 3800mm | 3800mm | 3800mm | |

| Weight | 50t | 60t | 55t | 65t | |

| Belt Conveyor | Hopper Volume | 3m³ | 3m³ | 3m³ | 3m³ |

| Loading Height | 2600m | 2600m | 2600m | 2800m | |

| Loading Width | 1900mm | 1900mm | 1900mm | 1900mm | |

| Dimensions (Width×Length) | 1000×6300mm | 1000×6300mm | 1000×6300mm | 1200×6500mm | |

| Crusher | Model | SC160 | SC250 | HP300 | HP400 |

| Inlet Dimensions | 75-360mm | 75-450mm | 60-200mm | 68-280mm | |

| Max.Feeding Size | 360mm | 450mm | 200mm | 280mm | |

| Min. Discharging Size | 8-25mm | 8-35mm | 8-45mm | 8-51mm | |

| Main Belt Conveyor | Dimensions (Width×Length) | 1000×9000mm | 1000×10000mm | 1000×10000mm | 1000×11000mm |

| Dumping Height | 3100mm | 3490mm | 3490mm | 3690mm | |

| Secondary Screen | Dumping Height | 4200mm | 4200mm | 4400mm | 4400mm |

| Model | HX1536 | HX1536 | HX1536 | HX1536 | |

| Sieve Dimensions | 1500×3600mm | 1500×3600mm | 1500×3600mm | 1500×3600mm | |

| Belt Conveyors at the Bottom | Dimensions (Width×Length) | 1000×5600mm | 1000×5600mm | 1000×5600mm | 1000×6500mm |

| Dumping Height | 3020mm | 3020mm | 3020mm | 3300mm | |

| Belt Conveyors to the Sieve | Dimensions (Width×Length) | 650×2100mm | 650×2100mm | 650×2100mm | 650×2100mm |

| Dumping Height | 1370mm | 1370mm | 1370mm | 1370mm | |

| Belt Conveyors for Discharging Material | Dimensions (Width×Length) | 650×10000mm | 650×10000mm | 650×11000mm | 650×11000mm |

| Dumping Height | 4200mm | 4200mm | 4400mm | 4400mm | |

| Diesel Engine | Power | 96kw | 132kw | 106kw | 132kw |

| Manufacturer | Carter Perkins | Carter Perkins | Carter Perkins | Carter Perkins | |

| The Main Machine | Power | 207.12kw | 297.12kw | 267.12kw | 362.12kw |

| Ways of Controlling | Wired/Wireless (optional) | Wired/Wireless (optional) | Wired/Wireless (optional) | Wired/Wireless (optional) | |

Proper daily checks and proactive maintenance are crucial for keeping tracked cone crushers running economically.

Focus on lubrication (quality, levels, temperature), managing liner wear (correct profile, timely changes), keeping the machine clean (especially seals and filters), and consistent choke feeding. These actions minimize major failures and maximize efficiency.

Preventative maintenance and smart operation are the best ways to control the costs associated with running a tracked cone crusher. Neglect leads to expensive repairs and lost production.

Liner Set Cost / Tons Produced Before Change). A slightly more expensive liner that lasts significantly longer and maintains efficiency can be cheaper overall. Consider trials with different materials (manganese steel grades) if appropriate for your rock type.Operational Best Practices

By focusing on these key areas daily and following the manufacturer’s full maintenance schedule, you can significantly reduce operating costs, extend the machine’s life, and maximize its productive uptime.

Considering power options? Electric tracked crushers are gaining popularity. They offer distinct benefits over traditional diesel models, especially in certain operational contexts.

Electric tracked cone crushers offer lower energy costs, reduced emissions (zero on-site), quieter operation, and potentially less maintenance (no diesel engine). However, they require an external power source (grid or generator).

While diesel-hydraulic drives have long been the standard for mobile crushers due to their self-contained nature, electric and diesel-electric options present compelling advantages.

The choice between diesel, diesel-electric, and direct electric depends on site conditions (power availability), fuel vs. electricity costs, environmental regulations, noise sensitivity, and mobility requirements. As manufacturers like ZONEDING, we can provide guidance and offer different drive options to best suit your specific operational context.

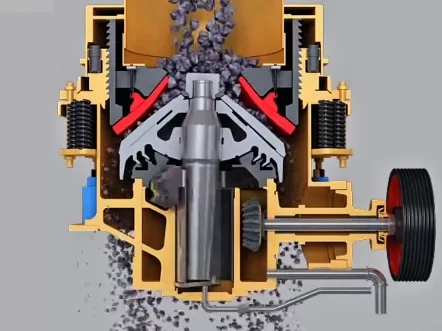

A Crawler Cone Crusher is a mobile, track-mounted crushing machine that uses a cone-shaped crushing chamber to compress and break down materials.

The material is crushed between a rotating mantle and a stationary bowl liner within the cone-shaped crushing chamber, providing consistent particle size reduction.

Crawler Cone Crushers offer excellent mobility, high crushing efficiency, and consistent product sizing for aggregate production and mining applications.

They are commonly used in quarrying, mining, aggregate production, and construction sites where mobility and consistent crushing are required.

Crawler Cone Crushers are ideal for crushing hard and abrasive materials like granite, basalt, gravel, and various types of rock.