全站搜索

Search the entire website

Search the entire website

Shaking table is also called shaker table, which is the commonly used gravity ore dressing equipment. Its separation efficiency is greater than the general gravity separation equipment.

Centrifugal gold concentrator utilizes the principles of a centrifuge to enhance the gravitational force experienced by feed particles to effect separation based on particle density.

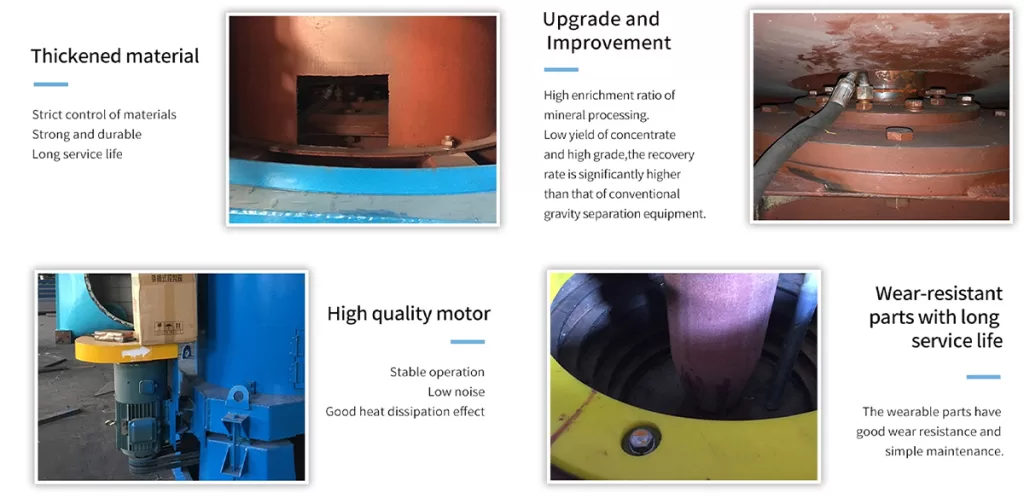

It can be used not only for alluvial gold mining, but also for recover the natural gold from hard rocks, to replace amalgamation,and recover gold from the tailing.applications shows that the recovery can be as high as 99%, and the concentrating ratio is up to1000 times.In recovering the natural gold in lode ore with size -0.074mm, the gold recovery is up to 98%.

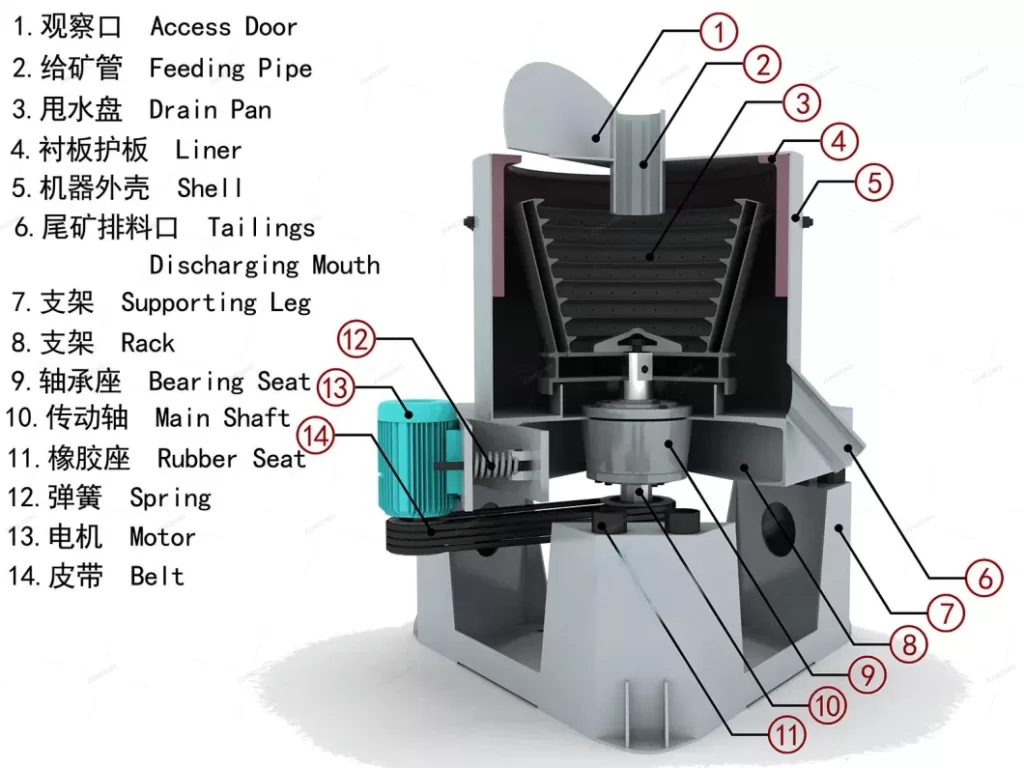

Centrifugal Concentrator use the principles of a centrifuge to enhance the gravitational force experienced by feed particles to effect separation based on particle density. The key component is cone shaped concentrate bowl. Feed material is fed as a slurry toward the center of the bowl from above. The feed slurry contacts the base plate of the vessel and due to its rotation, is thrust outward. The outer extremites of the concentrate bowl house a series of ribs and between each pair of ribs is a groove. During operation the lighter materials flows upward over the grooves and heavy mineral particles become trapped within them. Pressurized water is injected through a series of tangential water inlets along the perimeter of each groove to maintain a fluidized bed of particles in which heavy mineral particles can be efficiently concentrated.

Feeding, rotor, groove, motor, backwash water, PU lining plate, bearing, frame, tailings and concentrate discharge, etc.

| Model | BC-19 | BC-30 | BC-60 | BC-80 | BC-100 |

| Capacity(t/h) | 0.25-0.3 | 2-3 | 10-15 | 35-40 | 80-120 |

| Feeding size(mm) | 0-3 | 0-4 | 0-6 | 0-6 | 0-6 |

| Feeding density(%) | 0-50 | ||||

| Fludization water(m³/h) | 2-3 | 3-5 | 7-10 | 30-36 | 50-60 |

| Concentrate capacity(kg/time) | 2-3 | 10-20 | 30-40 | 60-70 | 70-80 |

| Power (kw) | 0.75 | 1.5 | 5.5 | 11 | 18.5 |

| Overall Size (mm) | 790*785*790 | 1180*1140*1250 | 1970*1670*1750 | 2300*1800*2200 | 2500*2000*2400 |

A Centrifugal Concentrator / Mining Centrifuge is a machine that uses centrifugal force to separate materials of different densities, commonly used in mineral processing.

Mining Centrifuges effectively process gold, silver, platinum, tantalum, and other valuable heavy minerals from ore and tailings.

Centrifugal Concentrators provide high recovery rates, low operating costs, and environmentally friendly mineral processing compared to traditional methods.

A Mining Centrifuge uses a rotating bowl or cone to create centrifugal force, separating heavier minerals from lighter materials based on density.

Consider feed rate, particle size, recovery rate, capacity, and maintenance requirements when selecting a Mining Centrifuge for your operation.