全站搜索

Search the entire website

Search the entire website

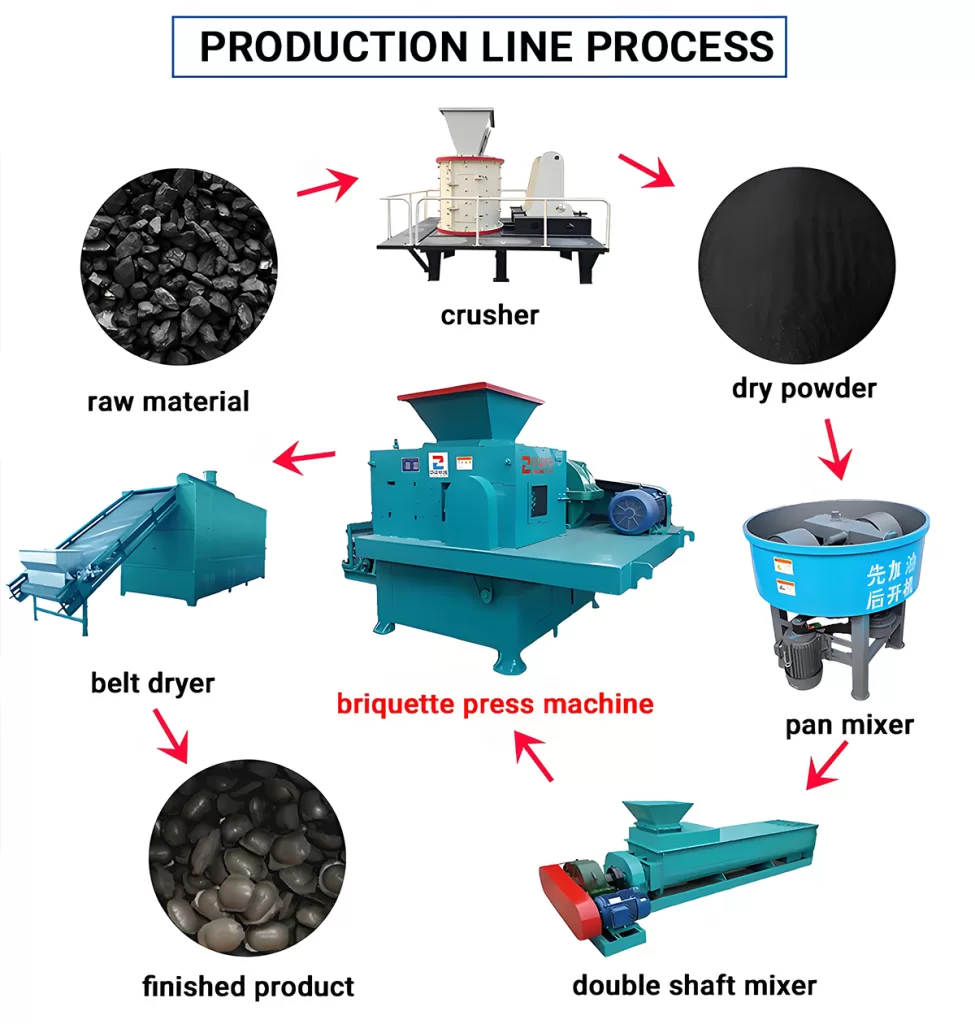

The briquette machine is a device that presses powdery materials into balls. It is easy to burn, smelt, store and transport materials in a spherical shape.

As one of China's leading experts in the manufacturing and supplying for the machinery and equipment of briquetting, compaction, drying and crushing processes. ZONEDING provides equipment and technology for the regeneration of valuable secondary raw materials from industry to biowaste.

Our technical team of process engineers and after-sales service support technicians have helped customers find the potential of their waste through briquette solution development. Our main goal is to maximize customer satisfaction by providing the greatest possible benefits from our products and services.

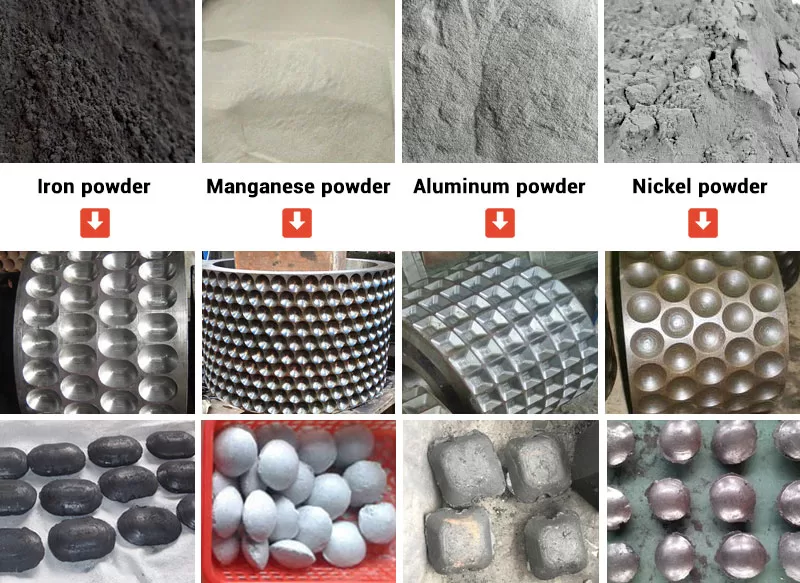

ZONEDING briquette machines can process 4 types of materials:

Depending on the materials and pellet, we can configure an affordable and efficient briquette machine for you.

The briquette machine is mainly used for pressing powdery materials that are difficult to form. It is characterized by large molding pressure, adjustable rotations of the main engine, and is equipped with a feeding device.

We understand that every material and application is different. We offer extensive customization options for our briquetting machines, including:

The briquette press machine is the core equipment of the briquetting making plant, and the supporting equipment includes hammer crusher, binder mixer, vertical dryer, biaxial mixer, feeder, mesh belt dryer, etc. According to the needs of customers, we will configure different solutions.

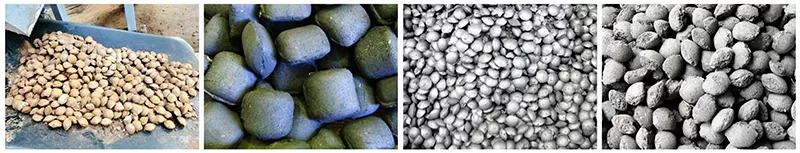

The final shaped balls can be made into spherical, square, pillow, and oval shapes. In addition, special shapes can be customized according to your needs.

ZONEDING offers you service support throughout the entire life cycle to ensure the smooth progress of your project:

Q.What should I need to set up a briquette plant?

A. Run a briquette plant is an easy way if you have proper material, make sure it has proper size, proper moisture, etc. Add proper material into the briquette machine and then the briquette is made! So, what our work is to make the material with that PROPER. And if purchasing from us, our engineer also can be out abroad to help you guiding set up your briquette plant.

Q. Is it possible for us to see a running briquette plant in China?

A. ZONEDING can arrange the visit if you want, but please contact us in advance for the arrangement as some of the plant is very far away.

Q. Can I do a briquette test by using one of your specific briquette machine before I buy the briquetter?

A. Absolutely. FREE TEST is acceptable now. Deliver your material with suitable weight we will back to you a test report with test video. Sample briquettes also can be taken for your further analysis.

Q. How long should I wait after purchasing the briquette machine from ZONEDING?

A. The machine making process will begin as long as the payment is made, the produce time will be around 10-20 days, and other time for arranging the shipping will be about 7 days. The shipping time will be much different in different places from 10 days to even 30 days.

Do I need to add binder when on briquetting?

A. It depends on the material and the working condition as well. Most of the material need to add binder when on briquetting, binder is also a good additive for protecting your briquetting system, but not all the materials need this, especially you are briquetting material like BIOMASS, LIME, etc. You can also briquette without binder by using hydraulic briquette press with high pressure, contact us and we will help to find your own briquette way.

A. Of course, almost all the materials can be briquette, the biggest problem for consideration should be running cost (electric, binder, workers, etc) and the investment (the briquette way, the plant equipment, etc).