全站搜索

Search the entire website

Search the entire website

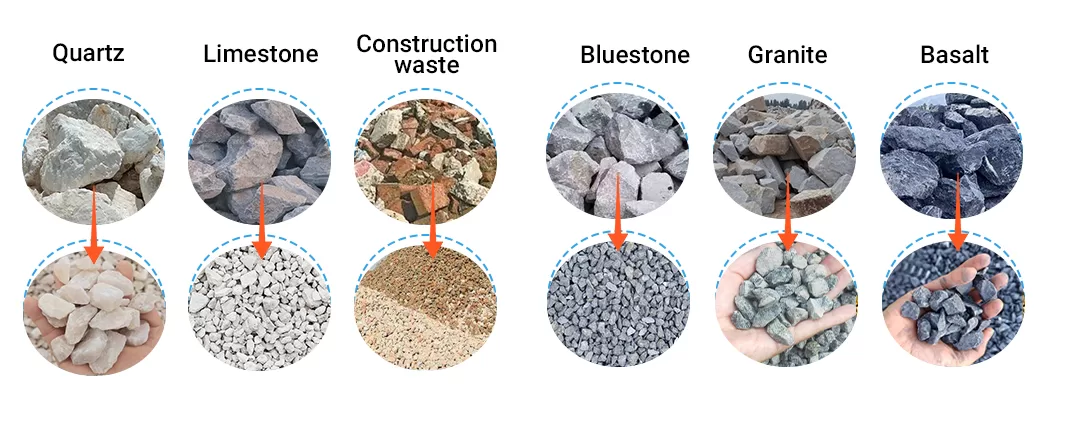

Impact crusher is widely used in the production of high grade stone materials used in highway, hydropower, artificial sand and stone, crushing, construction and other industries with its excellent performance.

This series impact crusher is able to crush coarse, medium and fine materials such as granite, limestone and concrete whose feeding granularity does not exceed 500mm and compression strength does not exceed 350MPa in many industries such as ore crushing, railway, highway, energy, cement, chemistry and constriction. The size of the discharging granularity is adjustable, and the crushing specifications are diverse.

Impact crusher can be used in primary and secondary crushing. They are suitable for crushing medium-hardness materials, such as limestone, construction wastes (concrete wastes, asphalt wastes, brick wastes, etc.).

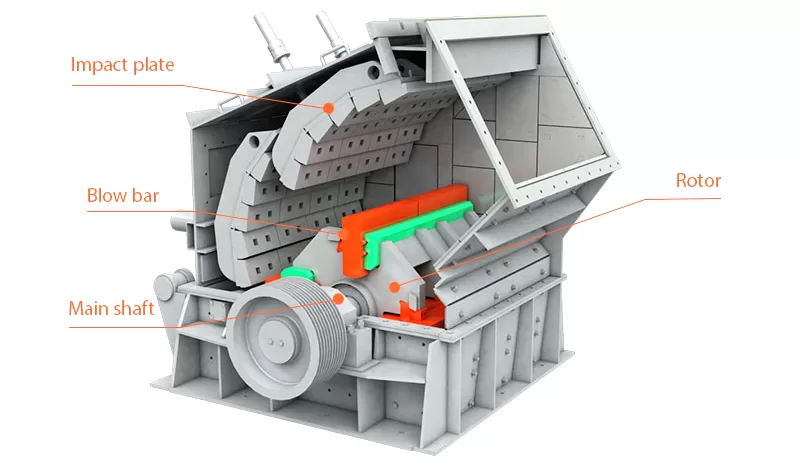

An impact crusher’s core is the rotor, fitted with rigidly attached hammers. Driven by the transmission, the fast-spinning rotor uses its inertia, via the hammers, to forcefully strike and shatter material. Secondary crushing occurs when the material hits the specifically designed impact plates within the crushing chamber, which provides space for this action. The entire assembly is supported by a robust frame that handles the operational forces, ensuring stability. Finally, discharge size adjustment devices allow users to control the final particle size of the crushed material to meet different production needs.

When the impact crusher is working, the motor drives the rotor through the V-belt, and the material is crushed by the high-speed impact of the hammer and is thrown to the impact bracket to break again, and then bounce from the impact surface to the impact area of the hammer again. This process is repeated until the material is crushed to the required size. The material flows from the first feed port to the first crushing chamber, and then into the second crushing chamber. When the crushed ore particle size is smaller than the gap between the hammer head and the impact plate, it will be discharged . This machine adopts a self-weight safety device on the rear rack. When the non-broken objects enter , the front and rear counter-attack frames will retreat, and the non-broken objects will be discharged from the machine body.

| Type | Feeder opening size(mm) | Max feeding size(mm) | Rotor size D*L(mm) | Capacity(t/h) | Power(kw) | Overall Dimension (mm*mm*mm) |

| PF-1007 | 450X750 | 250 | Φ1000X700 | 10-60 | 45 | 2330*1700*2560 |

| PF-1010 | 450X1100 | 300 | Φ1000X1050 | 50-90 | 55 | 2330*2010*2560 |

| PF-1210 | 450X1100 | 300 | Φ1250X1050 | 70-130 | 90 | 2640*2010*2850 |

| PF-1214 | 450X1450 | 350 | Φ1250X1400 | 90-180 | 132 | 2640*2400*2850 |

| PF-1315 | 650X1500 | 350 | Φ1320X1500 | 120-250 | 160-200 | 2930*2670*3150 |

| Type | Feeder opening size(mm) | Feed side length(mm) | Processing capability(t/h) | Power(kw) | weights (kg) |

| LF-150 | 820X980 | 100-200 | 100-200 | 90-200 | 12000 |

| LF-250 | 960X1360 | 200-400 | 200-400 | 180-250 | 17000 |

| LF-350 | 1050X1700 | 300-500 | 300-500 | 200-400 | 24000 |

Higher speed = more fines, better shape, higher wear. Lower speed = less fines, potentially lower throughput/shape quality. Balance needed based on feed and product spec.

Pre-screen feed, choked feed (if applicable), optimal speed, ceramic inserts, wear-compensating designs (adjustable curtains), regular blow bar rotation.

Tighter gaps/steeper angles = higher reduction, better cubicity, but more wear & potential blockage. Multiple aprons refine control. Final gap tunes top size.

Risk of severe damage to rotor/bars and jamming. Modern designs use heavy-duty parts, better locking, hydraulic relief. Pre-processing (magnets) vital.

Abnormal vibration (imbalance, bearing issues), erratic power draw (feed/jamming), unusual noise (loose parts, wear). Monitor trends for predictive maintenance.